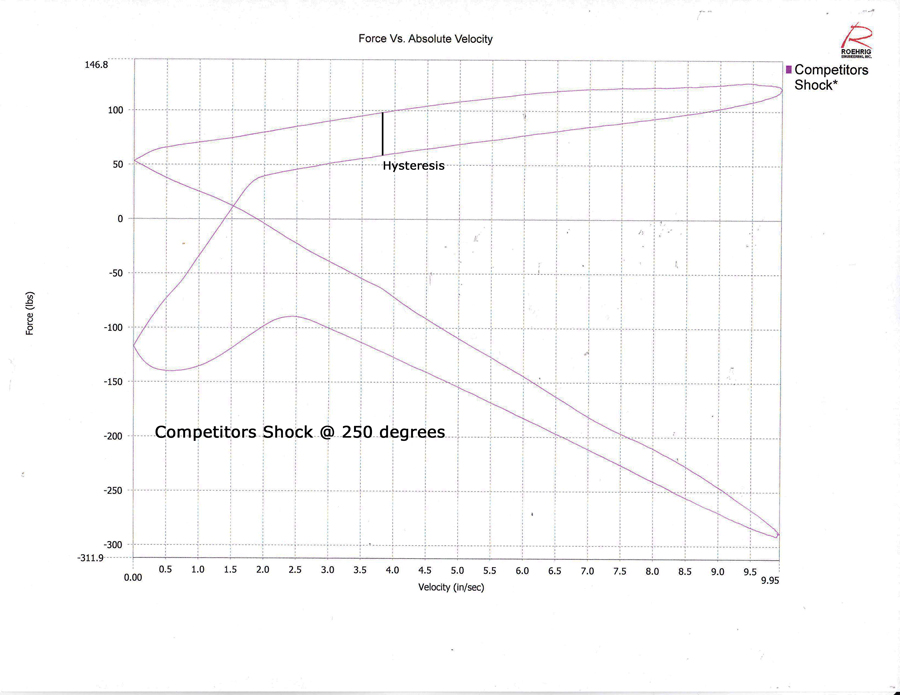

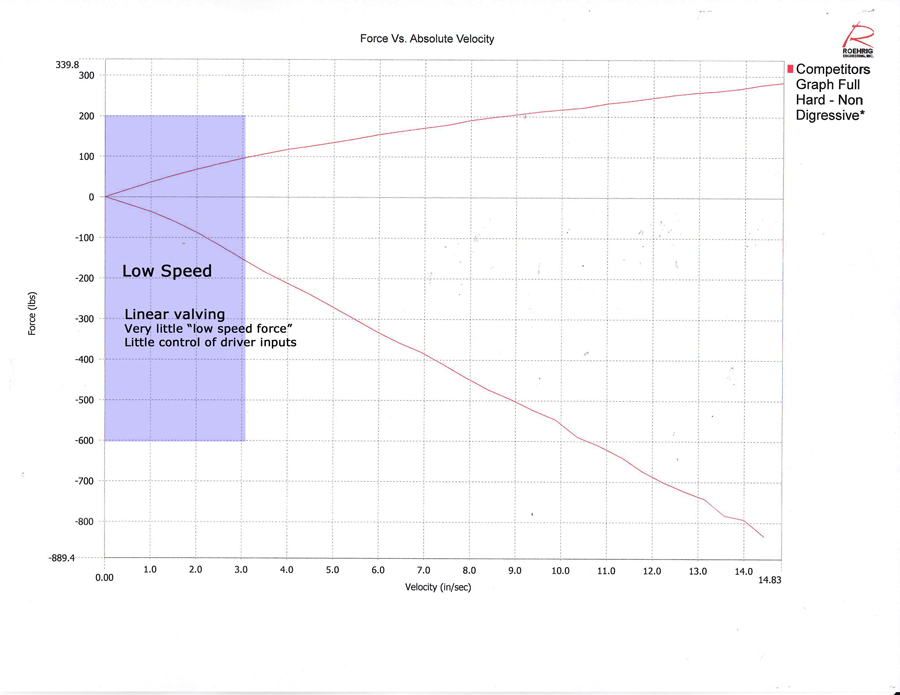

The graph below is of a competitors shock that is similarly priced to ours. This damper exhibits poor shock operation and is unacceptable in terms of hysteresis. Its actually worse then an oem shock. This shock was also tested at 250 degrees.

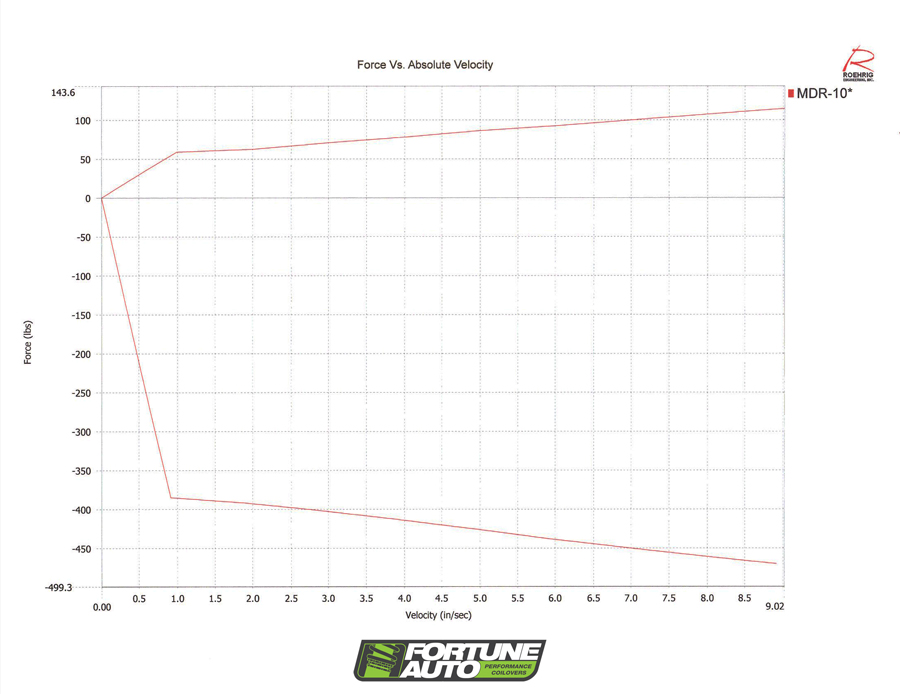

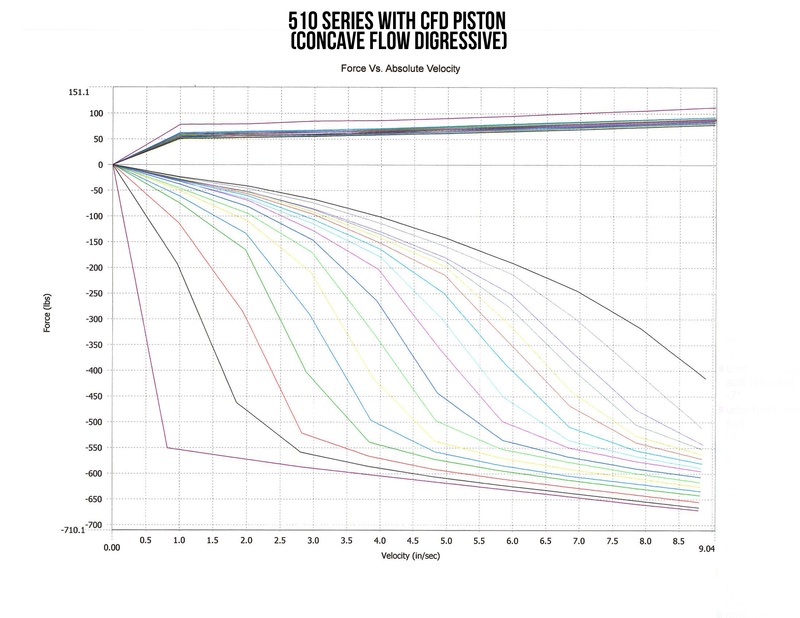

The graph below is of a 510 series shock. As you can see the graph has a knee in it. The shock exhibits much lower shaft speed force…again more control in roll and dive/squat situations.

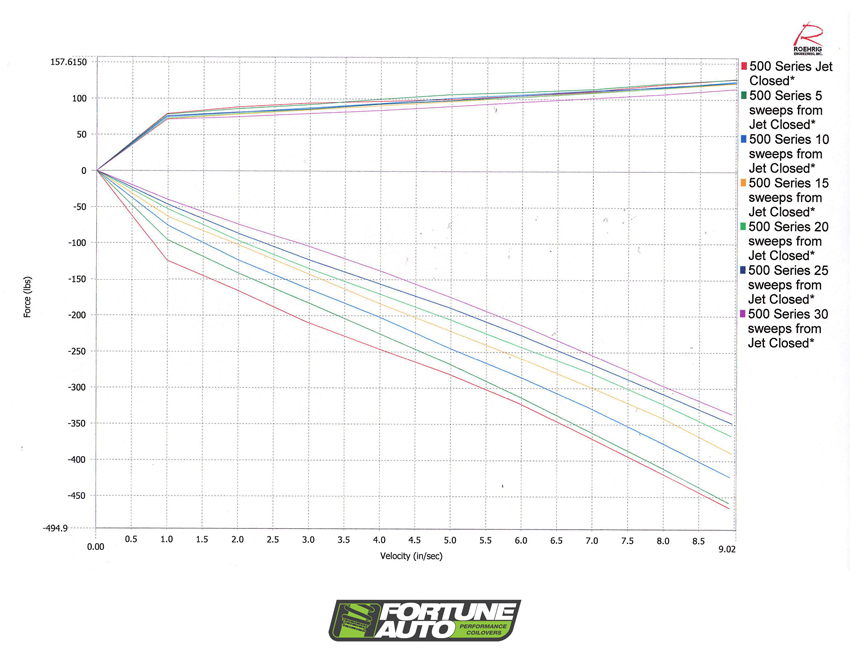

Below is a sweep PVP graph of one of our 500 series shocks from full soft to full hard. You will notice nice consistent damping changes. Many lesser shocks make little to no damping changes when the knob is turned.

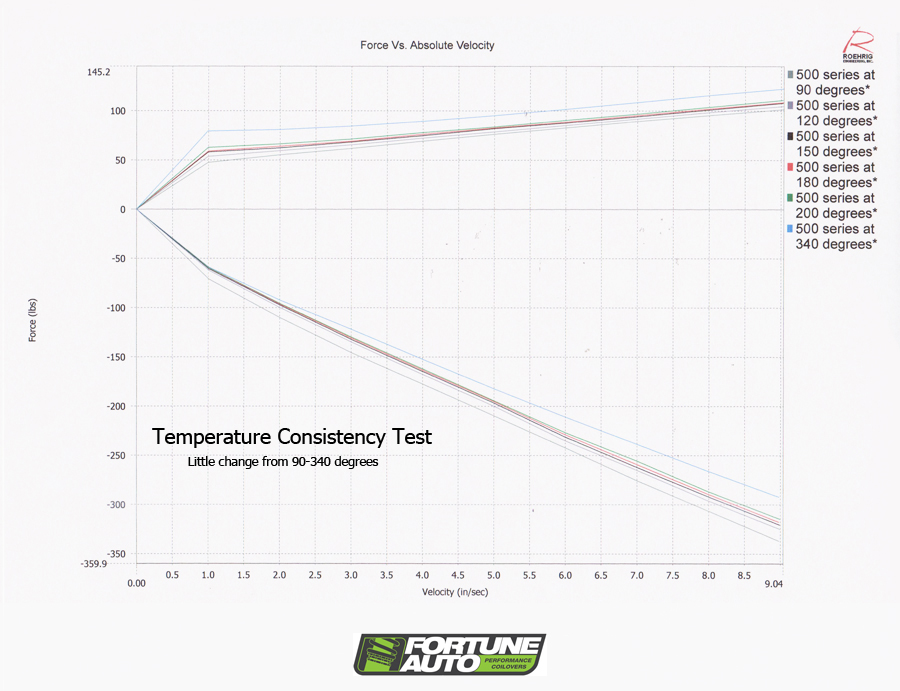

Considering that an egg will fry at 160 degrees Fahrenheit, it is pretty impressive that our shocks perform virtually the same at 90 degrees Fahrenheit as they do at 340 degrees Fahrenheit. This is accomplished by running over-sized shock bodies that hold more shock oil, high quality shims and heat resistant synthetic oil.

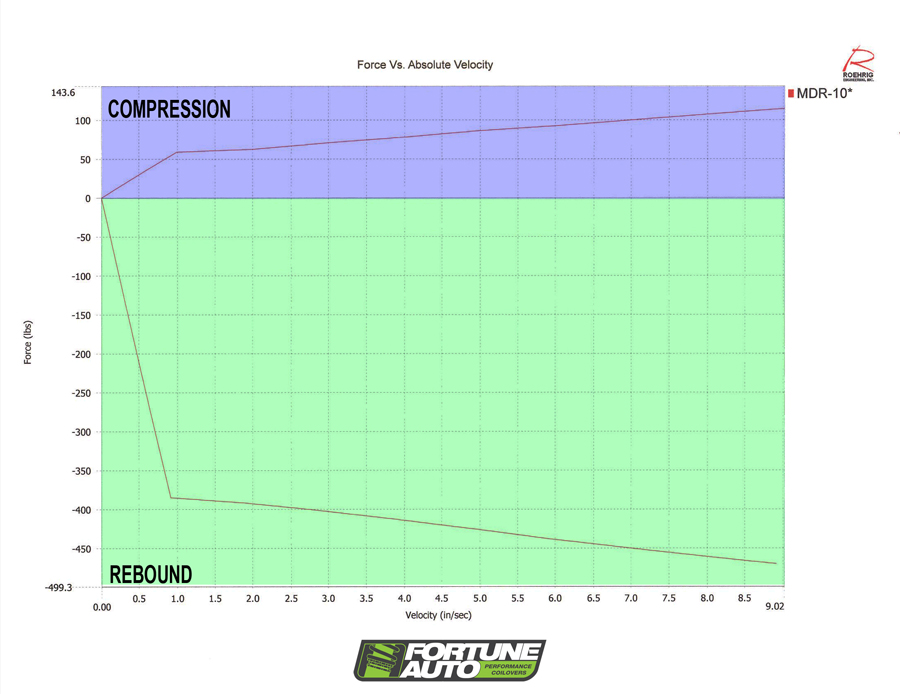

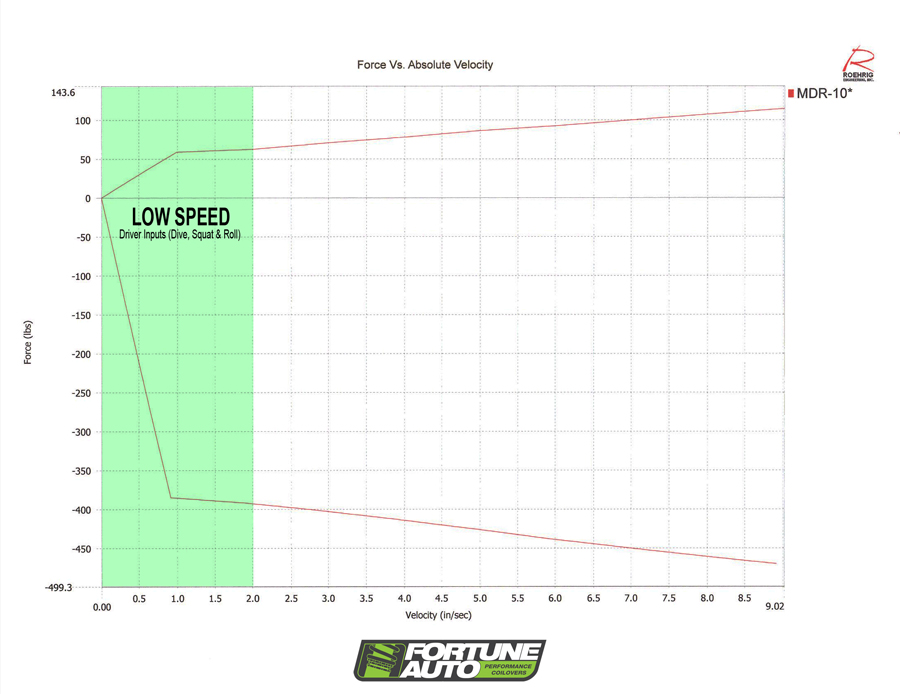

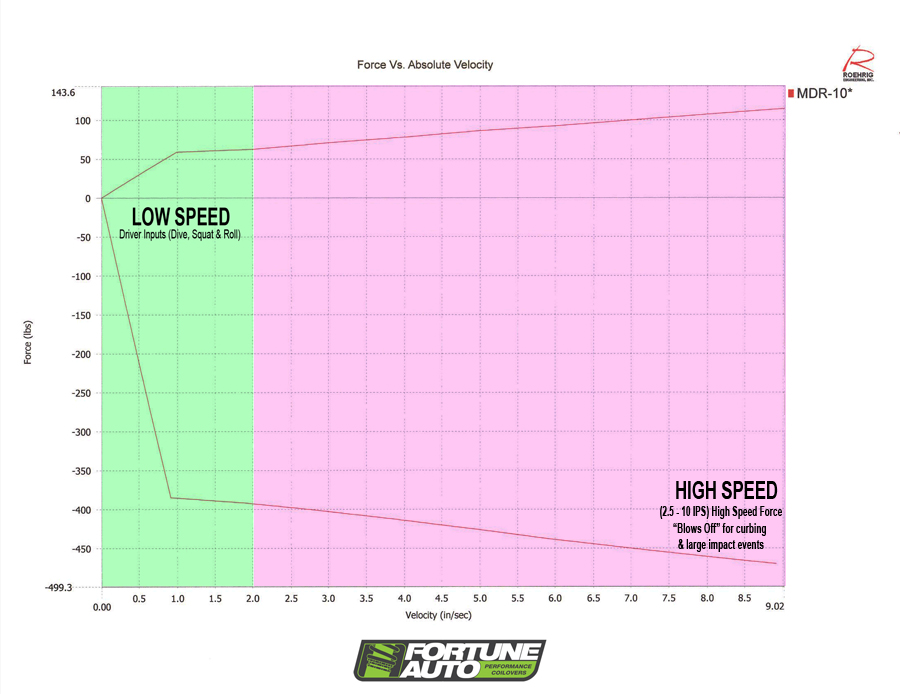

Lastly lets take a look at a shock dyno graph that is very digressive. More low speed force that tapers off in the high speed quadrants for a less jarring ride. Less rebound force in the high speed area of the graph translates into more mechanical grip when going over uneven track surfaces or berms.

Sweep graph of the “Ultra” Digressive 510 series shock.