Digressive Piston Basics

Fortune Auto dampers utilize Digressive and Ultra Digressive piston technology.

Digressive vs Linear Piston Technology

Digressive pistons produce a valving profile that is not straight or constant. As shaft speeds increase (thinking hitting a large bump at high speeds) the rate that damping force is created tapers off considerably. Digressive piston design exhibits low flow rate at low shaft speeds that provides a lot of resistance and control. Then the resistance rate increases when shaft speeds increase. Finally at a preset point (higher shaft speeds) the force rapidly tapers or “blows off”. This characteristic works tremendously well when going over large bumps or berms on a race track at high speeds

The opposite of digressive is linear. With a linear plot the rate of damping force generated varies very little. The damper exhibits a consistent feel through the entire stroke range. For example if you hit a specific size bump on the street or curbing on a race track you will feel the force of the impact. If you were to hit a bump that is twice as big, the impact feel will be twice as large. This is the opposite of a digressive piston.

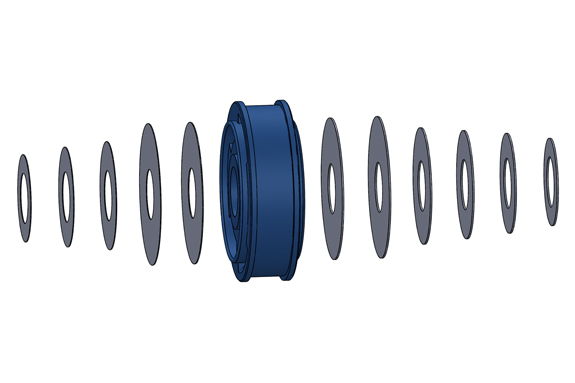

Ultra Precise Shim Stacks

Shims are deflection disks that cover up the port holes on a piston. They regulate the fluid flow which generates the force found in a damper. “Valving” or “re-valving” of a shock is accomplished by using a variety of shims that will ultimately provide enough resistance and damping ability for a particular application. Minute differences in the shims’ diameter and thickness are very critical; just a thousandths of an inch of variation in the dimensions can change a damper’s force profile up to + or – 25%. The shims’ consistency is crucial in matching shock absorbers to one another. Generation 7 dampers utilize a high-grade shim material made of Sandvik knife grade steel, ensuring precision matched dampers.